Summary

Conjugate heat transfer

In conjugate heat transfer simulation heat is transferred in several computational domains, for example through a gas and a solid. In many real-life applications the thermal properties of walls, heating elements, fans etc. are key design parameters. Conjugate heat transfer simulation can help to obtain a clearer picture of the parameter landscape and parameter sensitivity. This case is an example of a household appliance for which the operation conditions are optimized during the design phase of the product.

Strix Ltd. is a UK based company specialised in manufacturing safety controls for kettles and supplies to global brands and retailers such as Philips®, Tefal®, Tesco® and Walmart®. In this project provis process visualization assisted Strix in developing a bread toaster capable of producing toast in under 60 seconds by using forced convection from a fan inside the toaster. Strix engineers provided comprehensive CAD models of the toaster and provis created a solution strategy, test cases, case set-up as well as a day of training. The expertise of Strix’ engineers together with the CFD cases provided by provis enabled Strix to optimize the design of the so-called “Turbo Toaster”. The patented technology has already been awarded with the 2014 Thomas Miller award for Innovation and Independent Thinking.

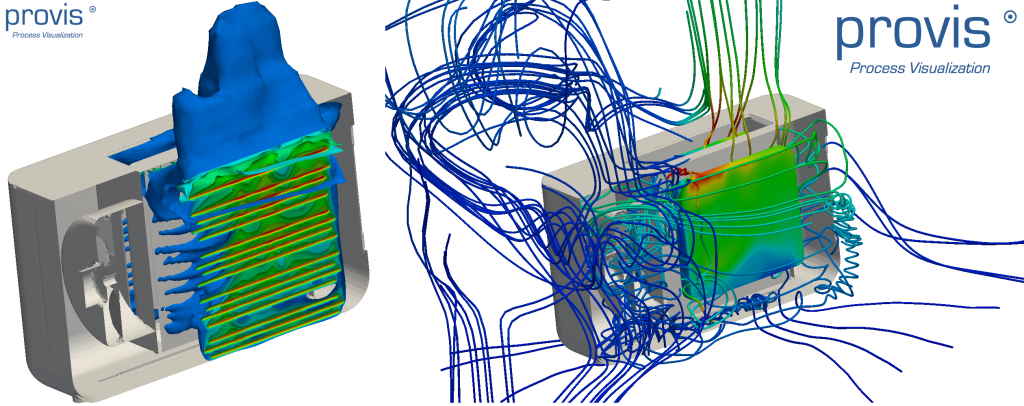

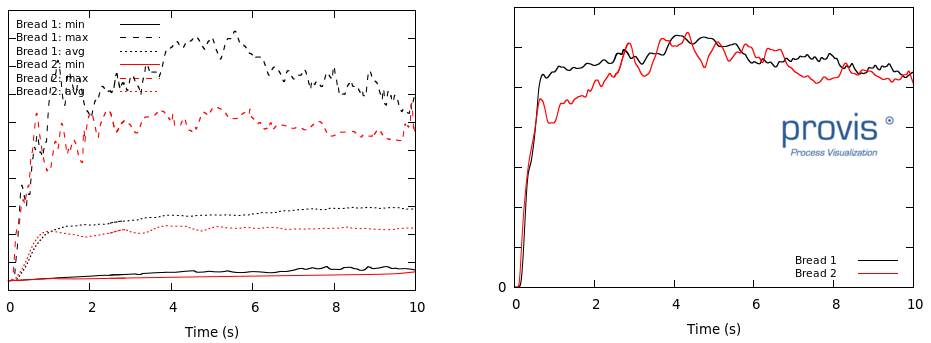

The qualitative data in the images below helps to identify hot spots for selected operational parameters and geometries. The key optimization variable is the uniformity of temperature on the surface of the bread. In this example, the bread surface can be analysed for relevant statistics, such as minimum, maximum, average, and spatial standard deviation over time. The graphs below show these statistics as a function of time. These statistics can be used for quantitative comparison of toaster performance for varying fan speed, fan cycle time, heat flux, and heating cycle. Strix Ltd. used this data to optimize the performance of the toaster. The final heating cycle had a short element pre-heat followed by a two stage process. The first stage using a fan, and the second stage with the fan switched off. The results were very successful; production has started and Strix received an award for innovative design.

minimum, maximum, and average (left) and spatial standard deviation (right).